Innovative Labeling: The Intersection of Printing and Graphics

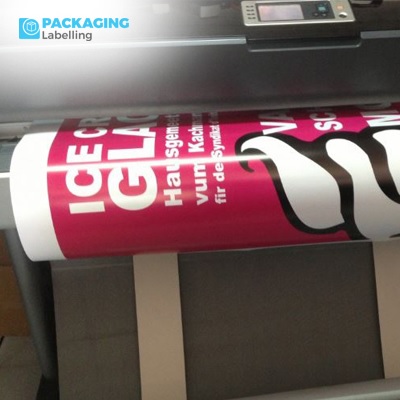

In the ever-evolving world of branding and packaging, innovative labeling is at the forefront of revolutionizing how products are perceived by consumers. The intersection of printing technology and graphic design has led to the creation of labels that are not only functional but also aesthetically pleasing, driving consumer engagement and brand loyalty. Modern techniques such as digital printing, UV printing, and flexographic printing are shaping the future of label manufacturing. Digital printing allows for high quality printing with faster turnaround times and lower costs, making it perfect for variable data printing, where each label can be unique. UV printing uses ultraviolet light to cure the ink, resulting in more durable and vibrant labels, especially beneficial for holographic labels and foil stamping. Flexographic printing is ideal for high-volume runs, providing consistent and high quality printing on various substrates.

In addition to these methods, creative labeling incorporates smart labels and innovative label adhesives to enhance functionality and consumer interaction. Smart labels integrate technology such as QR codes and NFC chips to provide additional information and interactivity, while advances in label adhesives ensure durability and sustainability. Holographic labels and foil stamping add layers of security and visual appeal, making products stand out on the shelves. The synergy between branding and packaging, supported by cutting-edge printing technology and graphic design, creates labels that not only attract attention but also effectively communicate the brand’s message and values, ensuring a lasting impact on consumers.

The Role of Graphic Design in Labeling

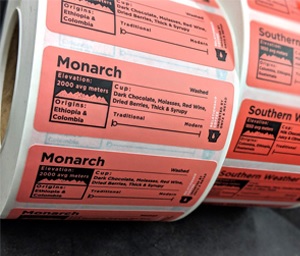

Graphic design plays a pivotal role in creative labeling. It is the art of combining text, images, and colors to create visually appealing labels that attract consumer attention. Good graphic design can make a significant difference in a product's market success by effectively communicating the brand’s message and values. The advancement of printing technology has provided designers with more tools to experiment with and implement intricate designs that were previously unattainable. Digital printing, for instance, allows for high quality printing and variable data printing, enabling each label to be unique. This customization is essential in branding and packaging, as it helps create a strong connection between the product and the consumer.

Modern label manufacturing techniques, such as UV printing and flexographic printing, have further expanded the possibilities for graphic design in labeling. UV printing uses ultraviolet light to cure the ink, resulting in more durable and vibrant labels, perfect for holographic labels and foil stamping that require high precision and detail. Additionally, smart labels and innovative label adhesives enhance functionality and consumer interaction, adding another layer of creativity to labeling. These advanced printing technologies not only improve the visual appeal of labels but also contribute to the overall effectiveness of branding and packaging, ensuring that products stand out in a competitive market.

Advancements in Printing Technology

The advent of digital printing has brought about a paradigm shift in the label manufacturing industry. Unlike traditional methods, digital printing allows for high quality printing with faster turnaround times and lower costs, especially for short runs. This method is perfect for producing labels with variable data printing, where each label can be unique, incorporating different graphics, text, or serial numbers. The flexibility and efficiency of digital printing make it an ideal choice for branding and packaging, allowing for personalized and creative labeling solutions that resonate with consumers. This advancement in printing technology has empowered designers to leverage graphic design in new and innovative ways, making labels more engaging and visually appealing.

UV printing is another technological advancement that has enhanced label manufacturing. UV printing uses ultraviolet light to cure or dry the ink as it is printed, resulting in more durable and vibrant labels. This method is especially beneficial for holographic labels and foil stamping, which require precision and a high level of detail. Flexographic printing remains a staple in the industry due to its versatility and efficiency. This method uses flexible plates and is ideal for high-volume runs, providing consistent and high quality printing on various substrates. Often used in conjunction with other techniques, flexographic printing supports creative labeling by enabling complex designs and special effects. Additionally, innovations in smart labels and label adhesives have further pushed the boundaries of what can be achieved in label manufacturing, ensuring that products not only look good but also meet functional requirements.

Innovative Label Features

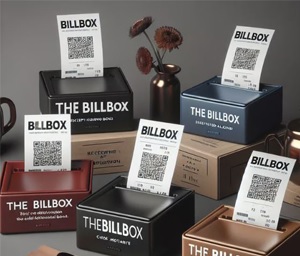

Modern labels are not just about aesthetics; they are also about functionality. Smart labels are becoming increasingly popular as they integrate technology to provide additional information and interactivity. These labels can include QR codes, RFID tags, and NFC chips, allowing consumers to access product information, track shipments, or even verify authenticity. The incorporation of smart labels into branding and packaging enhances the consumer experience and adds value to the product. Additionally, advancements in digital printing and variable data printing enable the production of these high-tech labels with high quality printing and customized designs. The use of advanced printing technology ensures that graphic design elements are not compromised, maintaining the visual appeal while adding functional benefits.

Holographic labels are another innovative feature that adds a layer of security and visual appeal. These labels are difficult to replicate, making them ideal for products that require authentication and anti-counterfeiting measures. Holographic labels also enhance the brand's image by giving a sense of exclusivity and high value. Techniques such as UV printing and foil stamping are essential for creating these intricate designs, ensuring precision and durability. Flexographic printing is often used in conjunction with these methods to achieve high quality printing on various substrates, supporting creative labeling solutions. Furthermore, label adhesives are a crucial yet often overlooked component of labeling. The right adhesive ensures that the label stays in place throughout the product's lifecycle, whether it’s exposed to moisture, varying temperatures, or rough handling. Advances in label adhesives have led to the development of eco-friendly and removable options, catering to the growing demand for sustainable label manufacturing solutions.

Branding and Packaging Synergy

The synergy between branding and packaging is essential for creating a cohesive brand experience. Labels are a critical touchpoint that conveys the brand’s identity and values to the consumer. High quality printing and graphic design work hand in hand to produce labels that stand out on the shelves and communicate the desired message effectively. The use of advanced printing technology such as digital printing, UV printing, and flexographic printing ensures that labels are not only visually appealing but also durable and precise. Digital printing allows for intricate designs and variable data printing, making each label unique and personalized, while UV printing enhances the durability and vibrancy of the labels, making them last longer and look better.

Creative labeling involves more than just slapping a logo on a product. It encompasses the use of various printing techniques like foil stamping to add metallic finishes, UV printing for enhanced durability, and digital printing for intricate designs. Each of these methods contributes to the overall perception of the product, making it more appealing and engaging to consumers. Additionally, the inclusion of holographic labels and smart labels adds layers of security and interactivity, enhancing the consumer experience. Label adhesives are also crucial in ensuring that labels stay in place under various conditions, from moisture to temperature changes. The advancements in label manufacturing have led to more sustainable and eco-friendly adhesive options, aligning with the growing demand for environmentally responsible branding and packaging solutions.

Exploring Future Trends

Looking ahead, the future of innovative labeling is poised to incorporate even more advanced printing technology and graphic design elements. Digital printing and variable data printing will continue to evolve, providing greater customization and personalization options for brands. This will enable companies to create unique experiences for their customers, fostering deeper connections and loyalty. As digital printing advances, we can expect even higher quality printing with faster production times and reduced costs, making it an indispensable tool for branding and packaging. Additionally, techniques like UV printing and flexographic printing will keep improving, offering more durable and vibrant labels that maintain their appeal over time. The continuous innovation in label manufacturing will ensure that creative labeling remains at the forefront of marketing strategies.

Smart labels will become more prevalent as the Internet of Things (IoT) expands. These labels will not only provide product information but also interact with smart devices, enhancing user experience and engagement. The integration of augmented reality (AR) into smart labels is an exciting development, allowing consumers to access immersive content by scanning the label with their smartphones. Holographic labels and foil stamping will continue to be popular for their security features and visual appeal, adding a sense of exclusivity to products. Sustainability will remain a key focus in label manufacturing. Innovations in label adhesives and materials will drive the development of eco-friendly labeling solutions. Brands will increasingly seek out high quality printing methods that minimize environmental impact, such as waterless printing and biodegradable inks. This commitment to sustainability will not only reduce environmental footprints but also resonate with eco-conscious consumers, reinforcing the brand’s values and enhancing its market position.

Conclusion:

In conclusion, the intersection of printing technology and graphic design is driving the future of innovative labeling. Techniques such as digital printing, UV printing, and flexographic printing are revolutionizing label manufacturing, enabling the creation of high quality printing with unique features like holographic labels and smart labels. As technology continues to advance, and as consumer demands evolve, the synergy between branding and packaging will play a crucial role in the success of products in the marketplace. By staying at the forefront of these innovations, brands can create creative labeling solutions that not only capture attention but also convey their values and message effectively, ensuring a lasting impact on their audience.